THE HEDLEY DIAL

BY

W. H. DAVIS

READ BEFORE THE SOUTH

WALES INSTITUTE OF ENGINEERS,

AT CARDIFF ON FRIDAY,

JANUARY 26th, 1923.

Excerpt from

Proceedings, Vol. XXXIM, No. 1.

EDITED BY THE

SECRETARY.

![]()

PUBLISHED BY THE

INSTITUTE, PARK PLACE, CARDIFF

PRINTED BY

SPOTTISWOODE, BALLANTYNE & CO. LTD.

LONDON, COLCHESTER & ETON

1928.

(All Rights of

Publication or Translation are Reserved.)

THE HEDLEY DIAL.

BY W. H. DAVIS.

(Managing Director of

John Davis & Son (Derby), Ltd.)

THE HEDLEY DIAL.

BY W. H. Davis.

(Managing Director of

John Davis & Son (Derby), Ltd.)

It

is quite impossible in a, short paper to deal with such a vastly interesting

subject as has been chosen for this meeting.

When

one considers that the firm of John Davis & Son (Derby), Ltd., have been

established for some one hundred years and have been making surveying

instruments during practically all that period, one is forced, however

reluctantly, to satisfy oneself with very brief descriptions of the improvements

which have been made on instruments turned out at All Saints Works, Derby, in

that time; and the writer has found it best to confine his paper almost wholly

to that particular surveying instrument with which the name of Davis‑Derby

' is most generally associated, namely, the miner's dial.

In

the beginning of the nineteenth century John Davis was making optical

instruments, compasses, etc., and was impressed with the possibility of

evolving something more useful for surveying purposes than the instruments then

in use. He accordingly set about making miners' dials.

The first pattern of miner's dial turned out by the firm was simply a compass box let into a mahogany case, with a very narrow socket. This case had a cover which was divided in two, hinged at the edges, and which folded over the compass box. Underneath these flaps were two strips which also folded over the compass box.

To

use this dial, the flaps were opened out flat, and the strips raised up for

sights. When closed, the depth was only about 1 inch, and the box was about 4

inches square.

Between

1830 and 1840, however, a much more substantial instrument was produced. The

compass box was 5 inches in diameter and had an inside vernier. The sights were

of metal and of the slot and horsehair type. The limb was fixed and the sights

folded over on top of the cover. The cover of this dial was of the same metal

(iron‑free brass) as the compass box and limb, and would only go on in

one position. The reason for this was that one‑half of the circumference

of this cover was divided for measuring vertical angles. Opposite the centre of

these divisions and on the edge of the circumference of the cover was a stud.

To use this instrument for measuring vertical angles, the whole dial was turned sideways, by means of a ball‑and‑socket joint, the collar of which was slotted to allow of this being done. A plumb‑bob was then suspended from the stud, and as the dial was moved in a vertical plane the string of the plumb‑bob indicated the angle of elevation or depression.

The vernier was fixed, but the compass circle was revolved by means of a rack and pinion, the milled head operating this mechanism being on top of the fixed limb and just by one sight. The bubble was at first mounted underneath the compass box, and later was put in the now familiar position.

For many years this type of dial was made, even after the introduction of the Hedley Dial, and even at this present day there are several still in use.

In 1850 John Hedley, one of H.M. Inspectors of Mines, being convinced of the inconvenience of miners' compasses and dials then in vogue, collaborated with John Davis (the founder of the firm), and the Hedley Dial was evolved.

In this connection it is interesting to quote from ' Notes on Instruments,' by the late W. G. Bligh, M.Inst.C.E., who, in describing the Hedley Rack Dial, says: “This pattern was first introduced as long ago as 1850 by Mr. John Hedley, Government Inspector of Mines, in collaboration with the late Mr. John Davis, the founder of the well‑known firm of John Davis & Co., Derby, by whose enterprise most of the improvements in miners' dials originated.”

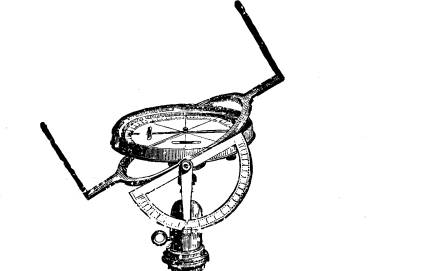

1850

Hedley Dial

While the main features of this original Hedley Dial are still the main features of all up‑to‑date mining dials, various improvements have been made at different times.

In order to appreciate these improvements, it is necessary to have some conception of the original Hedley Dial, and the writer will endeavour to describe it briefly.

The feature of Mr. Hedley's invention was the swinging limb. This construction superseded the old method of taking inclined sights (namely, by tilting the dial at right angles, as described above). The new 'Davis‑Hedley' method allowed the moving of the sights for taking vertical angles, 'by the limb being attached to trunnions which were fitted to the compass body ring.

This arrangement, besides enabling magnetic azimuths to be taken of lines lying at much greater inclinations than was possible with the simple forms of dial available before, also permitted of the provision of a divided vertical arc for measuring the inclinations with the compass box in its normal position, such measurements being also obtained much more rapidly. A divided semi‑circle was rigidly attached to the frame carrying the sights, so that the pointer recorded the inclination of the frame and also deductions per centum in the length of lines measured on the slope.

The compass box itself was, as now, cast from iron‑free metal, and the circle was engine divided.

The needle was set in motion by a lifter, actuated either by a screw underneath the box or by a wedge‑shaped slide, which raised or let down the needle as it was pushed in or pulled out.

The vernier was an inside one and read to three minutes; the clamping screws and milled head for operating the rack or vernier were, as now, below the dial box. In this old type, however, there was no tangent screw.

The joint was of the drop‑on ball‑and‑socket type.

In 1874 a 'Patent American Head' was introduced and patented in this country, the number of the patent being 2084, and the joint is now well‑known as the Hoffman joint. There were various types of this Joint, and these were recommended for use with different kinds of instruments, for although at the moment we are confining ourselves to miners' dials, the firm was also making theodolites, levels, clinometers, etc.

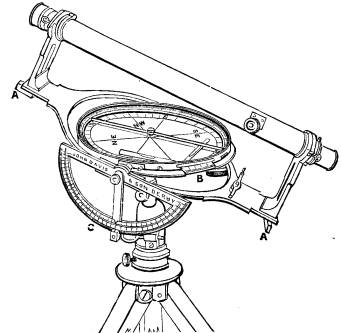

In 1875 John Davis & Son produced what is known as the 'Improved Hedley Dial.'

The essential feature of this instrument was an outside vernier in place of the inside. In this position many surveyors find it more useful and greater ease in reading, particularly so, one would imagine, in low workings. Moreover, there were now two graduated circles instead of one, and the mechanism was modified so that the vernier and needle readings corresponded, forming a mutual check. In the early part of 1877 a telescope was added to the Hedley Dial. The telescope was carried on two supports which fitted into the sight slots and were held in position by screws.

This necessitated rather a long telescope, and an improvement was made very shortly afterwards. The supports were let in somewhat nearer the compass box, as is the present practice, and were held in position in the same way, i.e., by screws from the under side of the swinging limb.

1877 Telescopic Dial.

They were also fitted with sights, so that, if desirable, one could take a backsight without reversing the telescope.

About this time, too, the needle was loosed by a catch on the side of the compass box, and where a telescope was provided two thumb‑clamps were fitted to the limb, which gave added rigidity to the dial when used for levelling.

In 1882 the firm introduced a modification of this Improved Hedley Dial, in which the vertical are was replaced by a fixed circular box, only 13/4 inch in diameter, with an index finger traversing the graduated disc.

This new arrangement was the outcome of an effort to have a vertical arc which would not interfere with the levelling screws.

It is of this instrument that Brough speaks when he says, It is the best instrument for colliery use.”

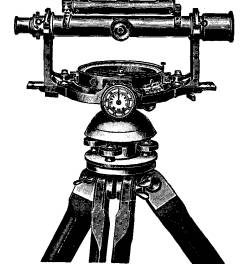

It was in the war years, however, that the greatest improvement took place, and this has continued right up to date, and so recently as this year a patent has been granted the firm for the 'Davis‑Derby' Standard Dial.

It was apparent by reason of the increasing number of dials which were going abroad that some method had to be adopted which would obviate most of the repair troubles of overseas surveyors, and after much thought the present form of dial was produced. This consists of the compass box plate and body ring being all in one casting. The benefit of getting rid of the separate plate ring will be appreciated by most surveyors. Besides being more rigid, the dial is much stronger and there are fewer screws to worry about.

In the last year or two this single casting idea has been extended to include the arc box, which is on the swinging limb and which is now quite enclosed. Internal focussing telescopes are now fitted to all the firm's telescope dials, theodolites, and levels.

Further improvements in the adjustments were to make larger and hollow‑milled heads, and the clamp screw and tangent screw have been reconstructed.

Where advisable, all these improvements have been embodied in the latest models of other types of Davis's surveying instruments, with very satisfactory results.

Modern Telescopic Dial. The Davis‑Derby Improved Dial.

Various types of joints are provided with the dials, according to the requirements of the particular surveyor, favourite amongst them for the telescope dials being the 4‑screw Hoffman with centering motion. For the non‑telescopic dials, the drop‑on joint is the most, favoured, owing to its extreme simplicity.

Legs have also received considerable attention as well as the instruments, various patterns being offered‑some surveyors favouring the telescopic type whilst others prefer the round socket‑jointed type.

A large number of dials other than the ' Standard ' dial are being made at All Saints Works. These include cranked dials, dials with overhead or quadrant arcs, and the ' Bligh ' dial, and just this year a special ' Bligh ' dial was constructed and a telescope with a special diaphragm fitted, about which more will be read in a paper by Professor Briggs and Mr. James Cooper, of Heriot Watt College, Edinburgh, on ' Tacheometry in Mines.'

Thus, very briefly, are mentioned some of the interesting improvements in Davis's miners' dials between 1823 and 1923.

Printed in England at the BALLANTYNE 'PRESS

SPOTTISWOODE, BALLANTYNE, & Co. LTD.

Colchester London & Eton