Room 1 contains lathes which have mostly been

specially constructed for the production of miners' safety lamps. Here may be

noted the ease and precision with which the various screw threads of a safety

lamp may be cut. Standards in steel being worked to in all cases, uniformity of

size, and the interchangeability of parts are ensured throughout. This

improved screw‑cutting tackle is employed for all apparatus manufactured

at All Saints' Works, and for some few years the various parts, especially

those of miners' dials and levels (which instruments will be more fully

demonstrated in Room 2), have been made to standard sizes, and are, therefore,

interchangeable.

In this room has

recently been constructed some improved apparatus for naval signalling,

invented by Lieut. INGLEFIELD, R.N. An order has been executed this year for

the German Navy, and Messrs. JOHN DAVIS & SON have received the gratifying

intelligence that it is the intention of Prince HENRY of PRUSSIA to adopt the

same throughout the whole German Navy; and this same apparatus is to be used

throughout the British Navy.

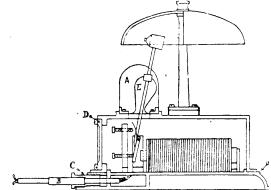

Mercier's Mining Bell.

A new form of ringing key is now being manufactured,

designed by Mr. M. Mercier, and also an electric signal bell. The special

feature in both bell and key is protection against damp and dust of pits and

all exposed situations; the contacts are enclosed in gas‑tight chambers,

so that any fear of igniting gas in a fiery mine is eliminated.

An improved form of insulator is

also exhibited which is designed by Messrs. MORGAN and JAMES chiefly for

colliery planes where it is desired to carry the wires side by side so that a

signal may be transmitted from any point in the plane. The insulator has two

transverse grooves which keep the wires at a proper distance apart. It is

intended to run the upper wire taut, and the lower loose, to avoid contact

between the insulators.

While on the

subject of electric signalling it will not be out of place to call attention to

a demonstration of the manner of connecting up signal wires so that they can be

used for speaking by telephone. In the engine room is fixed a telephone and

automatic switch, which cuts out the bell and battery when the telephone is in

use; at the distant end of the plane, or any desired point, the second

instrument is fixed, and in addition to this, or in place of it, portable

telephones can be carried in the pockets of the Deputies and hooked on to the

wires at any point. A special signal must of course be arranged when the

telephone is to be used. Though the above system works well, it is best to run

one separate wire for the telephones, the earth wire being common to both

signals and telephones.

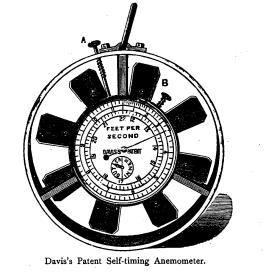

Room 2 is chiefly devoted to the manufacture of

scientific instruments other than electric, but here electricity plays an

important part in the production of finely divided and figured faces or dials

for such articles as Anemometers. The process of reproduction by electrotyping

of the faces for these instruments may be witnessed throughout. First, the

plate engraved by the machine to be seen in Room 3. This forms‑the

inverted copy or matrix‑then upon this is deposited the patrix, from

which further copies of the matrix are produced. Next comes the process of

waxing the lines and figures, and then the silvering process.

In this room are

constructed Magneto machines for shot firing and blasting on the " High

Tension " and Low Tension " principles, and also batteries for the

latter method, the battery being much lighter and cheaper than a Magneto

exploder of the same power.

As most of the

members are probably aware, the high tension fuse (which has been in general

use until recently), is fired by a spark jumping across two points in the fuse.

The low tension, which is the more reliable of the two, has only recently come

into use. It consists of a bridge of fine platinum wire between the two leading

wires; this bridge is heated by the current from the battery and thus fires the

fuse. One of the chief advantages of the low tension fuse is, that it can be

tested before use and a defective fuse detected. Mining bells and signalling

apparatus of various forms are also constructed in this room.

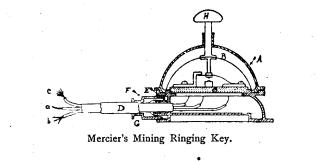

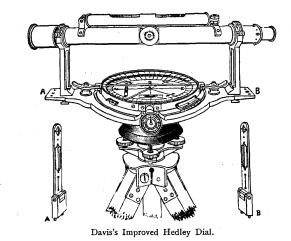

The Hedley Dial

will be familiar to most of the members, the firm having been actively engaged

in their manufacture for over half a

century; but as finality or perfection is never arrived at, and as it is

always endeavoured to produce the batch in hand something better than the last,

some points of novelty and improvement may be observed. As the boundaries of a

coal mine are more nearly approached the demand for more accurate instruments

increases, and year by year the Hedley Dial claims closer relationship to the

Theodolite. Thus, in the latest improved form, the Hoffman Patent joint has a

centering movement, self contained, and clamped by the same set of screws. The

limbs of this dial have been recently remodelled to give greater rigidity, and

at the same time weigh less than the pattern of its predecessor.

Aluminium is now

extensively employed in the construction of surveying instruments, particularly

for large foreign properties.

This wonderful

metal combines strength with extreme lightness. The transit Theodolite, now

nearing completion, is constructed wholly of aluminium, contains many points of

novelty, and weighs only 15lb. 2 oz. complete with its legs, against 29½lb. for

the same instrument in brass.

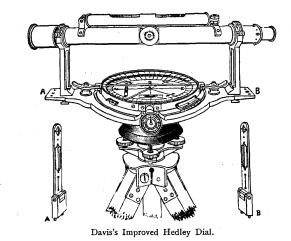

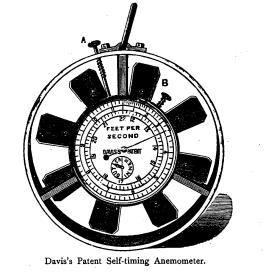

Dumpy Levels

with an improved beam, Clinometers in aluminium, and Biram's Anemometer, so

well known, may be seen in course of construction, but the Self‑timing

Anemometer, although it has found its, way to most parts of the mining

world, may not be so familiar.

Briefly

describing its action and construction, it will be seen that the fan, after

revolving freely and taking up a velocity due to the current of air, is engaged

in winding up a spring similar to the mainspring of a watch.

This spring

carries a hand over a graduated dial, which shows the current of air in feet

per second. To calibrate this anemometer, a special form of testing apparatus

has been constructed, and to ensure accuracy each instrument is separately

calibrated throughout the whole of its range.

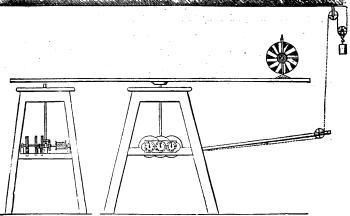

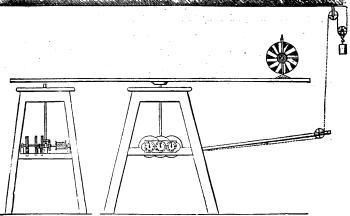

In ROOM 4

may be seen the machine for testing anemometers on the Biram principle,

illustrated above. The modus operandi consists in the passing of the

instrument through still air at various velocities, while the machine for

calibrating the Self‑timing Anemometer, by placing it in the same current

of air as a Biram Anemometer, may be seen in action; the various velocities

being obtained by a partial vacuum caused by a steam jet.

In Room 3,

the manufacture of safety lamp‑ gauzes is extensively carried on with a

small staff of workpeople by the aid of machine tools. Here may be seen the

various processes from cutting the blanks from the roll to a finished and well‑knit

gauze, passing through the hands of the operatives sixteen times before

completion. A most useful and ingenious machine is at work engraving and

dividing the faces of dials, which work was hitherto executed by hand. A

specially interesting feature of this machine is that it is driven by an

electric motor

which takes its

current from the Electric Station (to be shortly noticed more

fully and the

required variation in speed is obtained by switching in more or less

resistance, readily adjusted by turning the small handle as exhibited.

In Room 4

are stored the various parts of bonneted miners' safety lamps, and, in passing,

the practical value of reducing the manufacture to standard sizes may be

remarked, the shells of the lamps being interchangeable and all internal parts

being constructed to fit these shells. Lamps of all types, whether Marsauts,

bonneted Mueselers, bonneted Clannys, or any other of their modifications, can

be rapidly put together and consigned to their destination.

Here may be mentioned

the safety lamp cleaning machine shown in Room 5. This is the invention of Mr.

WOLSTENHOLM, of the Bestwood Coal and Iron Company. It has several advantages

over other machines of‑the‑kind. Arrangements are made‑for

unscrewing the ring holding the glass and gauze, for cleaning and polishing all

parts of the lamp, and for screwing the ring up again into position. An

eccentric imparts an oscillating movement to a brush which rapidly cleans the

gauze.

FIG.

1

Wolstenholme's Lamp Cleaning Machine.

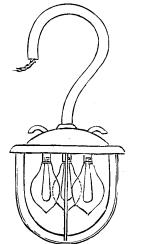

Special

fittings for the protection of incandescent electric lamps in dusty, damp. and

all exposed positions, are manufactured, and a large stock kept in readiness,

these being in considerable demand by various electrical engineering firms,

especially for lighting up the surface and underground of collieries, in which

the firm of JOHN DAVIS & SON have been of late years actively engaged.

A fitting specially for lighting a

sinking pit has been designed and is now in use at several collieries. It is exhibited

with its lamps alight, and consists of a cast‑iron dish‑strong

glass protector containing three incandescent lamps of 25 candle power each. A

strong flexible cable of twin conductors is told out from a drum at the top of

the pit shaft.

Room 5. A pioneer station for the distribution

of electric current is here installed, and has been at constant work for over

four years. This plant consists of an engine, dynamo and battery of sixty

accumulators, with its accompanying set of switches to regulate the current in

its various distributing cables ; voltmeters to indicate the pressure of the

current, ammeters to show the volume of current going out, and electricity

meters to ascertain the total amount of current consumed during any period.

Regulating switches with resistance coils to adjust the exact pressure to the

varying load, and an automatic switch to disconnect the dynamo from the

accumulators, should the pressure of the former fall below that of the latter.

The whole of the available current is daily in demand supplying neighbouring

hotels, shops, offices, and private houses with electric light, and it may be

here stated that from the day

that the current

was first` laid on" over four years ago, no single hitch or stoppage of

supply has occurred.

Electricity for

transmission of power is daily becoming recognised by coal‑owners as a

reliable agent, and already some hundreds.of horse power is being transmitted

electrically in‑mines‑ of this country, It was found impossible to

illustrate the application of electrical transmission

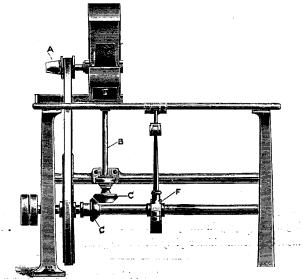

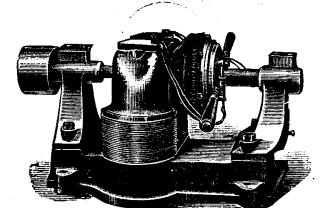

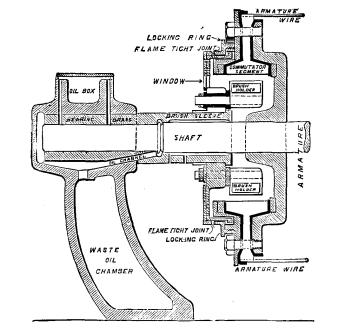

3 Brake H.P. Davis and Stokes' Patent Safety Motor

(Commutator closed.)

of power to coal‑cutting

and holing on the present occasion, but the same power applied to pumping may

be novel to some of the members.

Up to the present

time a danger has been felt to exist in the use of electric motors in fiery

mines, from the fact that bad setting or wearing of the brushes might result in

sparking, and the possible ignition of any gas that might be present ; in fact,

the use of electric motors in any mine where safety 'lamps are necessary has

hitherto‑been considered unsafe, and the progress of ‑electrical

transmission of power has thereby been greatly retarded.

Previous

attempts at the construction of a safe motor have taken. thel direction of

encasing either the whole machine,.the armature, or the

Safety Commutator open for cleaning

interior and brushes.

commutator and ‑brushes.

These arrangements not only introduced difficulties in the ventilation of the

armature, but also necessarily included a

considerable air space, so that when this space became filled with gas

it would be possible for an explosion to take place inside the case of such

violence as to entirely destroy the cover or case, and communicate with the

outside atmosphere, thus causing an explosion.

The arrangement

illustrated has been designed to overcome these difficulties, and is so

arranged that the commutator itself is practically equivalent to a locked

safety lamp enclosing the brushes, since it cannot be worked unless closed, and

cannot be opened while running; the junction between the fixed and the

revolving portions of the machine being made by a flame‑tight joint which

requires no packing and causes no friction.

The most marked deviation from the ordinary commutator is,

that instead of the brush contact being on the outside of the cylinder formed

by the commutator segments, this cylinder is bellow, and the brushes bear on

the inside face of the segments. The method of construction is as follows:-

The commutator ‑segments are clamped between a ring

and a disc, the latter being keyed on the shaft. This disc foirns a permanently

closed end to the commutator cylinder at the side nearest the armature.

Half Section of Commutator shewing bearing with elongated

brass.

The open end of

the commutator cylinder is closed by a disc sliding on the extended brass

bearing and carryingthe brush holders and brushes; and a clamping handle (not

shown in the illustration) provides for setting the disc and brushes in their

proper position. This disc, as stated, closes the end of the hollow cylinder,

the latter revolving with a clearance of 1‑32 in. from the disc; and in

order to avoid the chance of the disc with its brushes being withdrawn while

the machine is running, or started before properly closed, a locking ring is

provided, as shown in the illustration.

Small windows

are provided in the disc, by which any sparking at the brushes can be seen and

corrected, and the brushholders are fitted with springs working on the outside

of the disc, for adjusting their pressure while running.

When it is

necessary to clean the interior of the commutator and brushes, the locking ring

is unscrewed, and the disc, with brushes attached, is slid towards the bearing

as far as possible, thus leaving both commutator and brushes clear for cleaning

and inspection; means are provided for attaching a small slide rest, so that by

the use of a crank handle bolted to the pulley, the commutator can be turned up

in position, should this be required.

Carbon brushes

of a special type, admitting of very easy renewal, are used, thus obviating any

trouble that might occur from accumulation of copper dust within the commutator

with the ordinary copper brushes.

One of the chief

difficulties experienced by the firm is in making a judicious selection from

the various devices which are brought by inventors to be perfected,

manufactured, and introduced.

Amongst

inventions recently taken up at All Saints' Works may be

Mentioned:-

An Electric

Signalling Apparatus for the Navy;

An Electric

Indicator to show high and low water levels in tanks;

A Machine for

Closing and Unclosing Lead Locks of Miners' Lamps;

An Electrical

Time Checking Apparatus;

A Lamp for

Testing Small Percentages of Gas in Mines;

A System of

Humidifying the Air in Mines, so that coal dust is effectually damped.

The inventors

will, no doubt, in due course give the Members of the Federated Institution of

Engineers a more detailed description of their apparatus.

![]()

![]()

![]()